POWER YOUR BUSINESS!

CHARGE UP YOUR DAY!

ELECTRIFY YOUR MOBILITY

In industrial applications, in mining, in railway and transport companies, in ports, harbors, and shipyards, on campgrounds: in all of these situations and many more, it‘s imperative to safely and reliably distribute electric power in challenging or harsh conditions. As specialists for plugs and sockets, we‘ve packed our formidable CEE know-how into a top-notch product family for you. The PowerTOP Xtra plugs and connectors are available in 16, 32, 63, and 125 A versions. Many of them have been proving themselves in practice in a wide variety of work environments worldwide for years. All PowerTOP Xtra connectors feature our ingenious X-CONTACT contact sleeve technology.

PowerTOP Xtra: plugs and connectors for professional electricians!

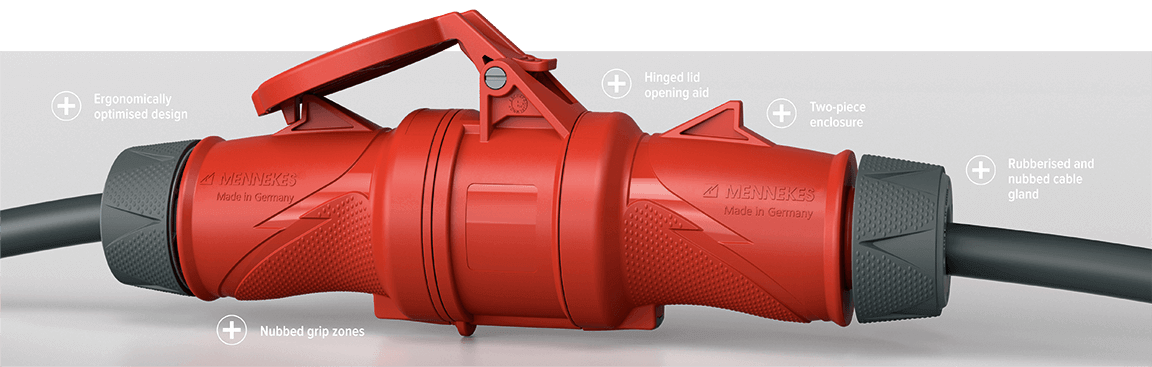

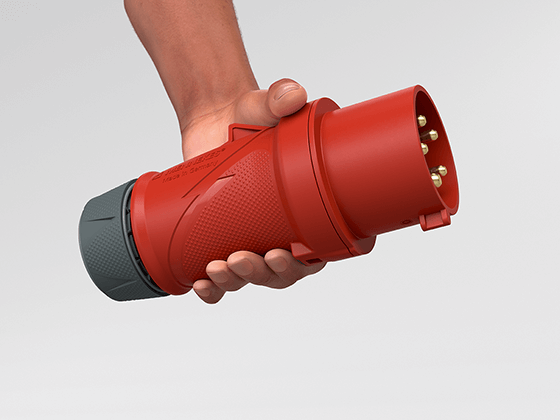

A special design and robust materials make sure that you can safely and easily use our PowerTOP Xtra plugs and connectors under even the most demanding conditions and that they will have an extra-long life. Thanks to an ergonomically optimised design, nubbed grip zones, and nubbed rubberised cable gland, our CEE plugs and connectors rest securely in the hand without slipping, also in wet and moist conditions, and can be connected and disconnected several thousand times. In the 63 and 125 A versions, the cable gland fits flusch to the enclosure, making it especially easy for you to keep the surfaces of the plug and connector clean.

Our plugs and connectors feature an integrated opening aid on the connector that makes it easy for you to open the hinged lid and hold it in that position. There‘s also a rotating lock between the front and the strain relief that can be quickly and securely closed without requiring you to tighten any screws. In the plugs and connectors of the 63 and 125 A versions (with IP67 protection class), the seals on the connector hinged lid and front of the plug are molded on and therefore impossible to lose.

The products of our PowerTOP Xtra family reliably support professional electricians across industries. Ideal for harsh, challenging working conditions, these plugs and connectors are extra-strong and deliver maximum protection:

The 16 and 32 A versions of our PowerTOP Xtra plugs and connectors have IP54 or IP67 / IP69 protection class. The 63 A version is available with IP54 or IP67 and 125 A exclusively with IP67. Our connectors for 63 and 125 A come with highly heat resistant contact carriers and are optionaly available with nickel plated contacts – the contact pins of the plugs are nickel plated. The plugs and connectors with 16 or 32 A are also available as PowerTOP Xtra R versions with the same robust features.

The waterproof plugs and connectors from our PowerTOP Xtra series, featuring the proven ErgoCONTACT screw connection technology and ergonomic enclosure design, have been expanded with a new feature. In addition to protection against temporary submersion (IP67), they also provide additional protection against water with particularly high pressure and high temperatures (IP69). This makes them suitable for long-term use in environments with frequent high-pressure cleaning.

Thanks to sealing with a screw cap and a bayonet ring, no water can penetrate the plugs and connectors. For use in areas with special environmental conditions, such as the food industry, the plugs and connectors with IP67 / IP69 protection are particularly well-suited. The double protection against temporary submersion and water with high pressure and high temperatures makes them robust and durable.

Even during repeated high-pressure cleaning, our plugs and connectors in IP67 / IP69 remain waterproof, and thanks to textured grip surfaces, they can be operated safely and easily even in moisture and wet conditions. When plugged, the rubberised bayonet ring keeps the plug tightly connected with the connector or receptacle.

Innovative technology for secure handling

Our contact sleeve technology X-CONTACT enables easy insertion and withdrawal with up to 50 percent less force, thanks to the X-shaped slits in the sleeves. In 63 and 125 A models, the inner walls of the contact sleeves are also grooved to ensure optimal and secure connection while automatically stripping away dirt. Even with rough handling and frequent insertion and withdrawal, there is no sign of wear, and the material remains durable, allowing the PowerTOP Xtra plugs and connectors to be used safely and reliably for many years.

We‘ve perfected the installation procedure for the products of our PowerTOP Xtra family: thanks to a self-finding thread for the enclosure, a locking slider, and a cable gland, you can quickly and easily install our plugs and connectors in the range from 16 to 125 A using a minimum of tools.

Our CEE plugs and connectors in 63 and 125 A are equipped with our proven screw contact connection technology. This makes them easy to install, and large amounts of electricity can flow reliably over the long term. For CEE plugs and connectors in 16 and 32 A, we have developed the innovative and convenient screw contact connection technology ErgoCONTACT. It allows for easy, secure, and ergonomically sensible installation. The models in 16 and 32 A are also available as PowerTOP Xtra S variants with the screwless connection technology SafeCONTACT.

All products of the PowerTOP Xtra family are available with screw terminals. We‘ve developed them further to create our easy-to-use ErgoCONTACT connection technology for 16 and 32 A plugs and connectors. They enable easy, secure and time-saving installation.

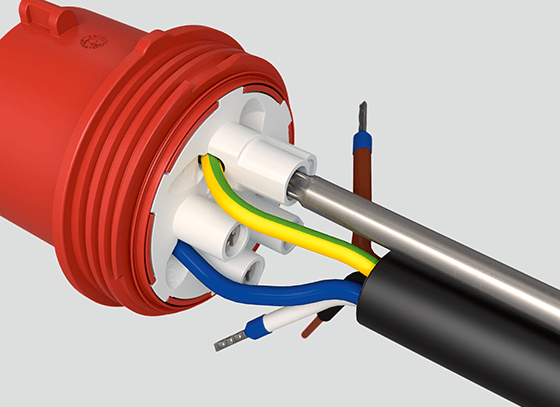

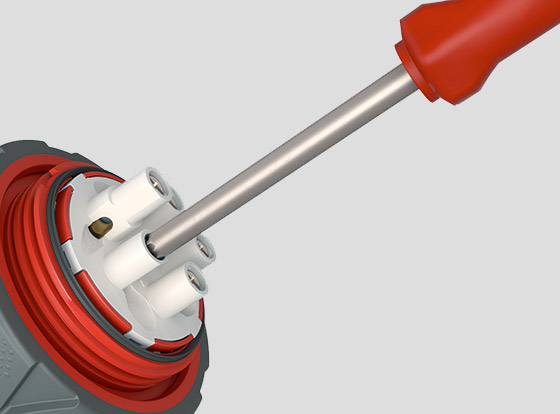

With ErgoCONTACT, you insert the screwdriver from the top instead of from the side. This makes it easier to achieve the required torque and the pressure is applied directly from the grip. All of the screws point in the same direction. This saves time, because it‘s no longer necessary to rotate the front part in your hand in order to tighten the contact screws of the individual poles one after the other.

Curved conductor guidance channels easily and securely move the conductor ends into the contacts.

The screw trajectory is additionally supported by a guide collar which prevents slide-off and minimises the danger of injury.

Each contact has only one screw: a captive combination head screw that is permanently integrated in the guide collar in the factory and can be turned using either a Phillips or a flathead screwdriver. Since only one screw has to be set for each contact, installation is easy and time-saving.

Our 16 and 32 A plugs and connectors are also available in PowerTOP Xtra S versions with our proprietary SafeCONTACT screwless connection technology. It eliminates the need to peel the insulation off the wires or otherwise prepare them, letting you make connections more than twice as fast and eliminating subsequent maintenance!

Plug in conductors without stripping, lever down the terminals with a screwdriver – that‘s it.

In one work process the insulation is separated and a secure contact connection established.

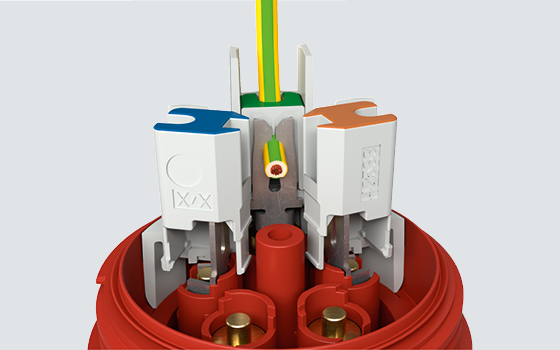

In the 63 and 125 A models, the contact screws are space-savingly integrated next to the guide collar into the front part of the plug or connector.

The stripped conductors are simply inserted – they can be used with or without wire end sleeves.

Two contact screws ensure a secure hold of the conductors. These are tightened diagonally and permanently keep the conductors in position.